Cayimid

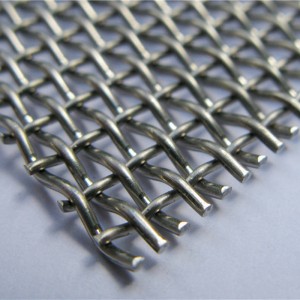

Waxyaabaha: 304,304l, 316,316l, 317l, 904l, Duflex Sty

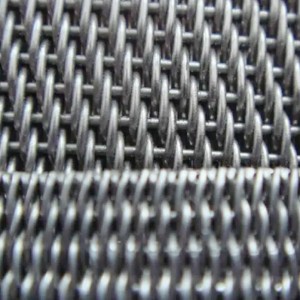

| Twill Wacdutions faahfaahinta | |||||||

| Nambarka wax soo saarka | Warp mesh | Mes | Dhexroor dhexroor | Nin cafis ah | Meel furan | ||

| aasaasi ah | mm | aasaasi ah | mm | (%) | |||

| Stw-30 / 0.4 | 30 | 30 | 0.0157 | 0.399 | 0.0176 | 0.45 | 28.0 |

| Stw-40 / 0.35 | 40 | 40 | 0.0138 | 0.350 | 0.011 | 0.29 | 20.1 |

| Stw-40 / 0.4 | 40 | 40 | 0.0157 | 0.400 | 0.009 | 0.24 | 13.7 |

| Stw-46 / 0.25 | 46 | 46 | 0.0100 | 0.254 | 0.012 | 0.30 | 29.2 |

| Stw-60 / 0.25 | 60 | 60 | 0.0100 | 0.254 | 0.007 | 0.17 | 16.0 |

| Stw-80 / 0.17 | 80 | 80 | 0.0067 | 0.170 | 0.006 | 0.15 | 21.6 |

| Stw-100 / 0.12 | 100 | 100 | 0.0047 | 0.120 | 0.005 | 0.13 | 27.8 |

| Stw-120 / 0.11 | 120 | 120 | 0.0043 | 0.110 | 0.004 | 0.10 | 23.1 |

| Stw-150 / 0.8 | 150 | 150 | 0.0031 | 0.080 | 0.004 | 0.09 | 27.8 |

| Stw-200 / 0.06 | 200 | 200 | 0.0024 | 0.060 | 0.003 | 0.07 | 27.8 |

| Stw-270 / 0.04 | 270 | 270 | 0.0016 | 0.041 | 0.002 | 0.05 | 32.3 |

| Stw-300 / 0.038 | 300 | 300 | 0.0015 | 0.038 | 0.002 | 0.05 | 30.3 |

| Stw-325 / 0.036 | 325 | 325 | 0.0014 | 0.036 | 0.002 | 0.04 | 29.7 |

| Stw-350 / 0.035 | 350 | 350 | 0.0014 | 0.035 | 0.001 | 0.04 | 26.8 |

| Stw-400 / 0.025 | 400 | 400 | 0.0011 | 0.028 | 0.001 | 0.04 | 31.4 |

| Stw-500 / 0.025 | 500 | 500 | 0.0010 | 0.025 | 0.001 | 0.03 | 25.0 |

| Stw-635 / 0.02 | 635 | 635 | 0.0008 | 0.020 | 0.001 | 0.02 | 24.2 |

XUSUUSNOW: Faahfaahin gaar ah ayaa sidoo kale lagu heli karaa iyadoo loo eegayo shuruudaha macaamiisha.

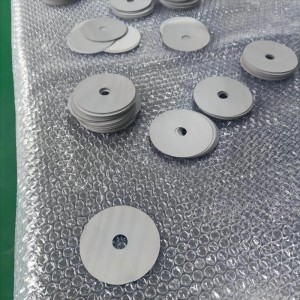

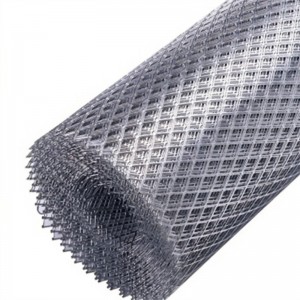

Codsiyada: Badanaa waxaa lagu isticmaalaa baaritaanka walxaha walxaha iyo qulqulka, oo ay kujirto xajmiga patrochemical fitrochemical, cuntada iyo dawada loo isticmaalo, dib-u-warshadaynta caagga ah iyo warshadaha kale.

Ballabka caadiga ah ayaa u dhexeeya 1.3m iyo 3m.

Dhererka caadiga ahi waa 30.5m (100 cagood).

Cabirrada kale waa la habeyn karaa.

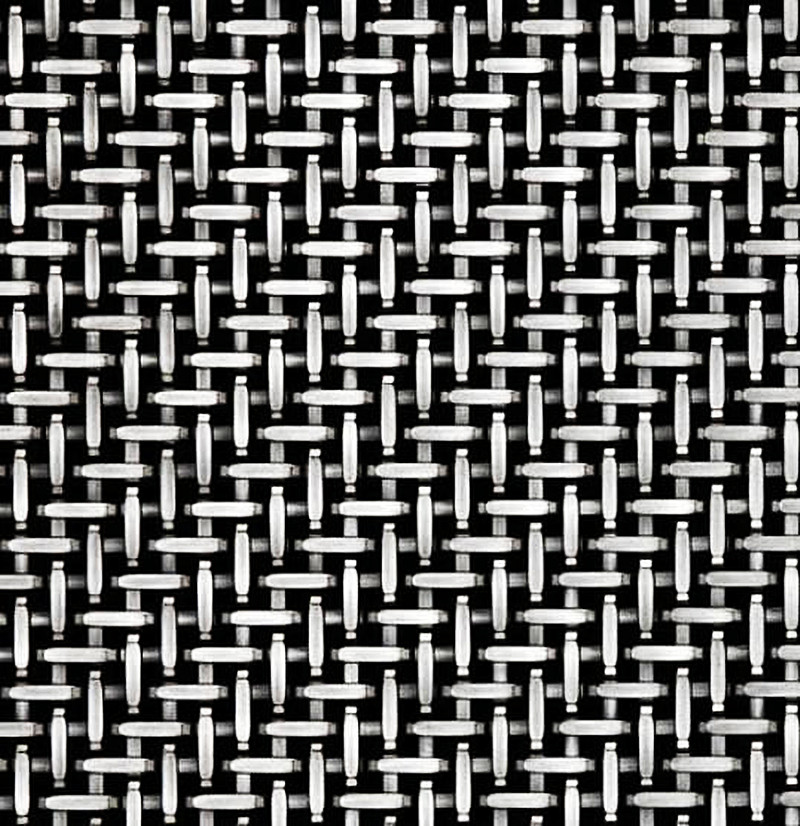

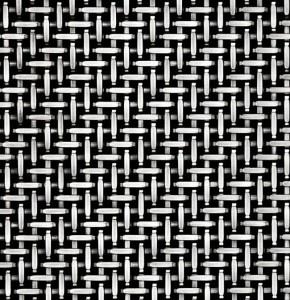

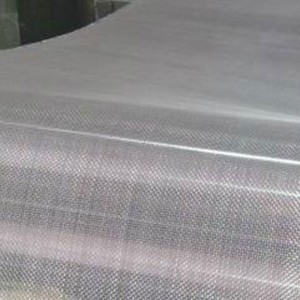

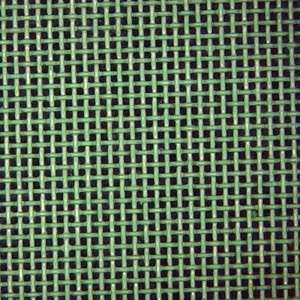

Sida magaceedu tilmaamo, maro kharashka birta birta ahi waa maro qurux badan oo leh silig bir ah oo bir ah. Dharka jilicsan ee birta ee birta ah ayaa leh xoog sare iyo aashito iyo iska caabbinta aashitada iyo alkali. Waxay ku habboon tahay kiimikada, dawooyinka, caafimaadka, warshadaha fudud, isgaarsiinta, batroolka iyo warshadaha kale. Baadhitaanka iyo shaandheynta alaabada granular iyo u isticmaal suumanka koontada, dubitaanka, buuxinta, iwm.

Wiish: dhar cad iyo shaashad

Tilmaamaha: iska caabinta aashitada, iska caabbinta alkali, iska caabinta heerkulka sare, xoogga TSensile iyo iska caabbinta baabi'inta

Adeegsiga