Cayimid

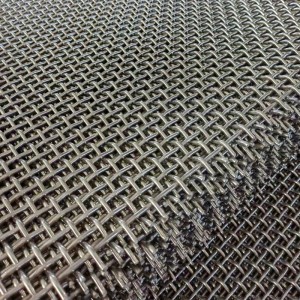

Waxyaabaha: 304,304l, 316 / 316l, 317l, 904l, Duflex steel iwm.

| Sharaxaadda shaashadda ee cad | |||||||

| Nambarka wax soo saarka | Warp mesh | Mes | Dhexroor dhexroor | Nin cafis ah | Meel furan | ||

| aasaasi ah | mm | aasaasi ah | mm | (%) | |||

| SPW-2 / 3.0 | 2 | 2 | 0.1180 | 3.0 | 0.382 | 9.70 | 58.4 |

| SPW-4 / 1.6 | 4 | 4 | 0.0630 | 1.6 | 0.2 | 4.75 | 56.0 |

| SPW-4 / 1.2 | 4 | 4 | 0.0470 | 1.2 | 0.203 | 5.16 | 65.9 |

| SPW-6 / 1.2 | 6 | 6 | 0.0470 | 1.2 | 0.120 | 3.04 | 51.6 |

| SPW-8 / 0.7 | 8 | 8 | 0.0270 | 0.7 | 0.098 | 2.49 | 61.5 |

| SPW-10 / 0.8 | 10 | 10 | 0.0315 | 0.800 | 0.069 | 1.74 | 46.9 |

| SPW-10 / 0.5 | 10 | 10 | 0.0200 | 0.508 | 0.080 | 2.03 | 64.0 |

| SPW-12/1.6 | 12 | 12 | 0.0235 | 0.60 | 0.060 | 1.52 | 51.6 |

| SPW-12 / 0.5 | 12 | 12 | 0.0200 | 0.508 | 0.063 | 1.61 | 57.8 |

| SPW-14 / 0.6 | 14 | 14 | 0.0235 | 0.597 | 0.048 | 1.22 | 45.0 |

| SPW-14 / 0.5 | 14 | 14 | 0.0200 | 0.508 | 0.051 | 1.31 | 51.8 |

| SPW-16 / 0.6 | 16 | 16 | 0.0235 | 0.597 | 0.039 | 0.99 | 38.9 |

| SPW-16 / 0.45 | 16 | 16 | 0.0175 | 0.445 | 0.045 | 1.14 | 51.8 |

| SPW-18 / 0.4 | 18 | 18 | 0.0160 | 0.406 | 0.040 | 1.00 | 50.7 |

| SPW-20 / 0.5 | 20 | 20 | 0.0200 | 0.508 | 0.030 | 0.76 | 36.0 |

| SPW-20 / 0.4 | 20 | 20 | 0.0160 | 0.406 | 0.034 | 0.86 | 46.2 |

| SPW-24 / 0.35 | 24 | 24 | 0.0140 | 0.356 | 0.028 | 0.70 | 44.1 |

| SPW-30 / 0.3 | 30 | 30 | 0.0120 | 0.305 | 0.021 | 0.54 | 41.0 |

| SPW-30 / 0.25 | 30 | 30 | 0.0100 | 0.254 | 0.023 | 0.59 | 49.0 |

| SPW-35 / 0.25 | 35 | 35 | 0.0100 | 0.254 | 0.019 | 0.47 | 42.3 |

| SPW-40 / 0.25 | 40 | 40 | 0.0100 | 0.254 | 0.015 | 0.38 | 36.0 |

| SPW-50 / 0.2 | 50 | 50 | 0.0080 | 0.203 | 0.012 | 0.30 | 36.0 |

| SPW-50 / 0.15 | 50 | 50 | 0.0060 | 0.152 | 0.014 | 0.36 | 49.0 |

| SPW-60 / 0.15 | 60 | 60 | 0.0060 | 0.152 | 0.011 | 0.27 | 41.0 |

| SPW-60 / 0.13 | 60 | 60 | 0.0050 | 0.127 | 0.012 | 0.30 | 49.0 |

| SPW-80 / 0.13 | 80 | 80 | 0.0050 | 0.127 | 0.008 | 0.19 | 36.0 |

| SPW-80 / 0.1 | 80 | 80 | 0.0040 | 0.102 | 0.009 | 0.22 | 46.2 |

| SPW-90 / 0.11 | 90 | 90 | 0.0045 | 0.114 | 0.007 | 0.17 | 35.4 |

| SPW-90 / 0.1 | 90 | 90 | 0.0040 | 0.102 | 0.007 | 0.18 | 41.0 |

| SPW-100 / 0.11 | 100 | 100 | 0.0045 | 0.114 | 0.006 | 0.14 | 30.3 |

| SPW-100 / 0.1 | 100 | 100 | 0.0040 | 0.102 | 0.006 | 0.15 | 36.0 |

| SPW-120 / 0.09 | 120 | 120 | 0.0035 | 0.089 | 0.005 | 0.12 | 33.6 |

| SPW-120 / 0.08 | 120 | 120 | 0.0030 | 0.076 | 0.005 | 0.14 | 41.0 |

| SPW-150 / 0.06 | 150 | 150 | 0.0025 | 0.064 | 0.004 | 0.11 | 39.1 |

| SPW-180 / 0.06 | 180 | 180 | 0.0023 | 0.058 | 0.003 | 0.08 | 34.3 |

| SPW-200 / 0.05 | 200 | 200 | 0.0020 | 0.051 | 0.003 | 0.08 | 36.0 |

| SPW-250 / 0.04 | 250 | 250 | 0.0016 | 0.041 | 0.002 | 0.06 | 36.0 |

| SPW-270 / 0.035 | 270 | 270 | 0.0014 | 0.035 | 0.002 | 0.06 | 39.4 |

| SPW-300 / 0.03 | 300 | 300 | 0.0012 | 0.030 | 0.002 | 0.05 | 41.7 |

| SPW-325 / 0.028 | 325 | 325 | 0.0011 | 0.028 | 0.002 | 0.05 | 41.2 |

| SPW-400 / 0.025 | 400 | 400 | 0.0010 | 0.025 | 0.002 | 0.04 | 36.0 |

XUSUUSNOW: Faahfaahin gaar ah ayaa sidoo kale lagu heli karaa iyadoo loo eegayo shuruudaha macaamiisha.

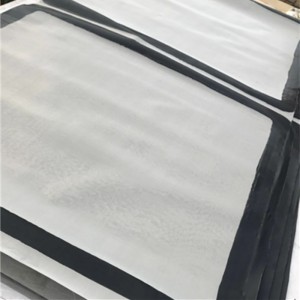

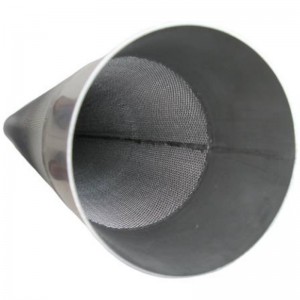

Codsiyada: Badanaa waxaa loo isticmaalaa baaritaanka walxaha walxaha iyo qulqulka, oo ay kujirto marinka patrochemical (cuntada iyo dawada loo isticmaalo, baaritaanka qalabka dhismaha iwm.

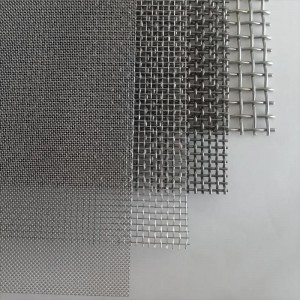

Ballabka caadiga ah ayaa u dhexeeya 1.3m iyo 3m.Customer-wax soosaarka gaarka ah waxaa laga heli karaa ballac 5.0m.

Dhererka caadiga ahi waa 30.5m (100 cagood). Cabirrada kale waa la habeyn karaa.

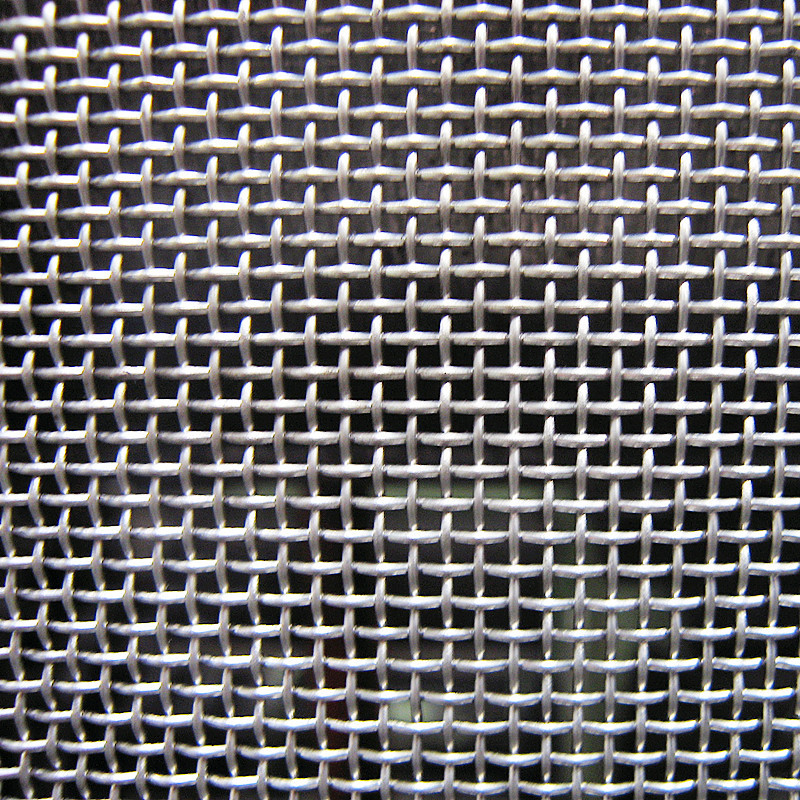

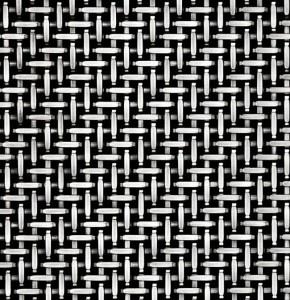

Mesh silig bir oo bir ah ayaa ka mid ah nooca mesh oo bir aan bir lahayn, kaas oo lagu gooyn karo sawirro faahfaahinno kala duwan. Qayb isku dhafan ayaa waliba aqbali kara agab soo gala sidii loo qaban lahaa. Shirkaddeenu muddo dheer waxaa loo galiyay in la soo saaro alaabo sare oo buluug ah oo tayo leh oo bir ah, waxaana lagu qalabeeyay qalab kormeer oo kala duwan. Waxaa loo habeyn karaa iyadoo loo eegayo shuruudaha macaamiisha.

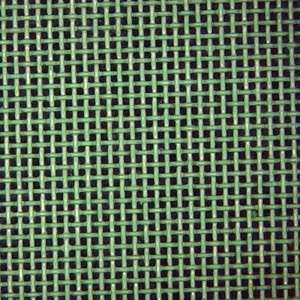

Geedihii wax soo saarka wax soo saarka: Dhex-dhexaadiyaha Wire iyo Ift Cross waa isku mid, silig kasta oo isku dhex-dhexaad ah, oo silig kasta oo iskutallaab ah, oo kasta oo qudhafeysan ah ayaa ka gudbaya fiilooyinkii hore ee Weft.

Dayactirka maalinlaha ah ee MEBE MESH: Mashiinka dharka lagu dhaqo waa shaqada aasaasiga ah ee dayactirka qalabka, kaas oo ay tahay in hay'ad ahaan hay'ad tahay oo loo jaangooyo. Dayactirka joogtada ah ee qalabka, kootada shaqada iyo kootada isticmaalka sheyga waa in la dejiyaa, iyo qiimeynta waa in lagu fuliyaa iyadoo la raacayo kootada. Dayactirka joogtada ah ee qalabka waa in lagu daraa qiimeynta waxa ku jira nidaamka musaafurada qandaraaska ee aqoon isweydaarsiga.